SoundClean - ultrasonic solution to prevent soiling

Preventive cleaning without chemicals – efficient, retrofittable, durable.

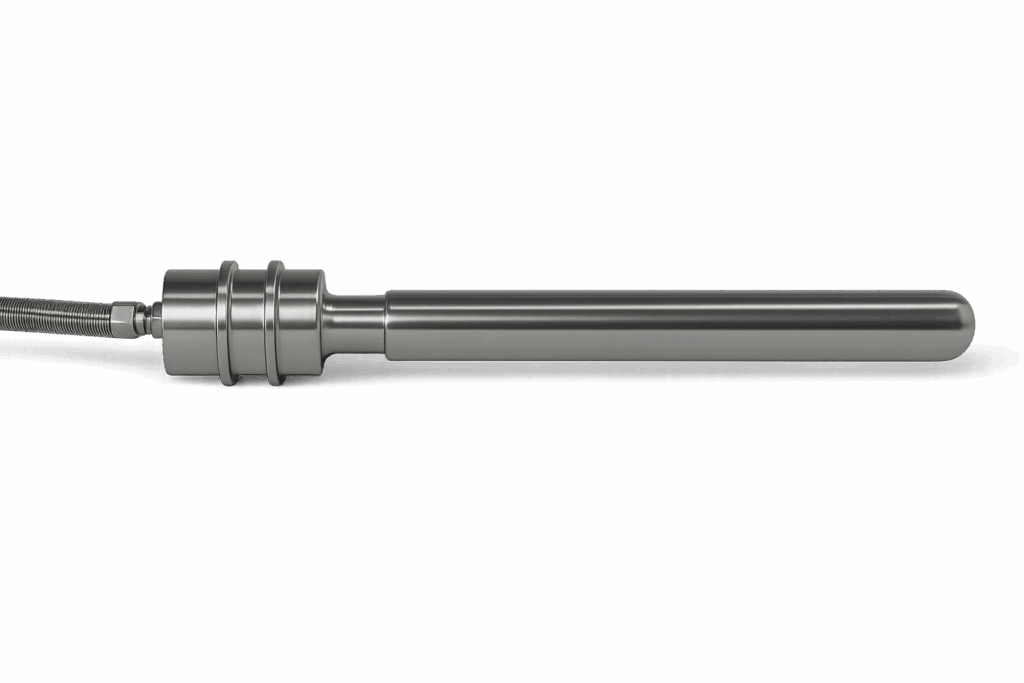

SoundClean is an innovative ultrasonic system that prevents deposits, soiling and fouling on metallic surfaces from the outset. The system was developed by Multi Sonic GmbH and will be distributed by Stemotech for the Austrian market in future – as a supplement for heat exchangers, pipelines and other process-critical components.

Key Facts

- Technology: High-frequency ultrasonic vibrations for preventive cleaning

- Mounting: Via welding adapter or coupling screws - can also be retrofitted

- Supply: Switch cabinet with 400 V / 16 A, touch display, remote maintenance capable

- Protection class: High IP standard, suitable for indoor and outdoor use

- Function: Generates cavitation & turbulence, prevents dirt from sticking

- Advantages: No use of chemicals, no downtimes, no regular disassembly necessary

Industries & applications

Energy & power plant technology

Food & beverage industry

Food technology (milk cooling, pasteurization)

Chemistry & Pharma

Pulp & Paper

Oil, gas & water treatment

Cement, lime and bulk materials industry

Case studies

Heat exchanger

SoundClean keeps heat exchanger surfaces permanently free of biofilm and deposits - without cleaning downtime

Silo discharge (cement)

prevents blockages caused by adhesion to the inner walls of funnels or pipes

Process pipes

Ultrasound protects against contamination in long pipelines, e.g. with oily or viscous media

Let's find the best cooling solution for your company together!

SoundClean - Ultrasonic technology for clean systems and stable processes

Contamination and deposits are among the most common causes of efficiency losses and maintenance work in industrial processes. With SoundClean, Stemotech now offers a technology that solves these problems preventively – before they even arise.

The system is based on high-frequency mechanical vibrations in the ultrasonic range. These generate turbulence and acoustic cavitation in the medium, which prevents particles from sticking to metallic surfaces. The effect: heat exchangers, pipes or silo walls remain permanently clean, cleaning cycles are eliminated and the service life of the components increases significantly.

SoundClean can be easily integrated into existing systems – via welding adapters or prepared threaded holes. The system is controlled via a robust, remotely maintainable control cabinet with touch display. The system is also suitable for outdoor areas thanks to its high IP protection.

Whether heat exchanger, process pipe or silo outlet – SoundClean protects your system, increases operational reliability and reduces maintenance costs to a minimum.