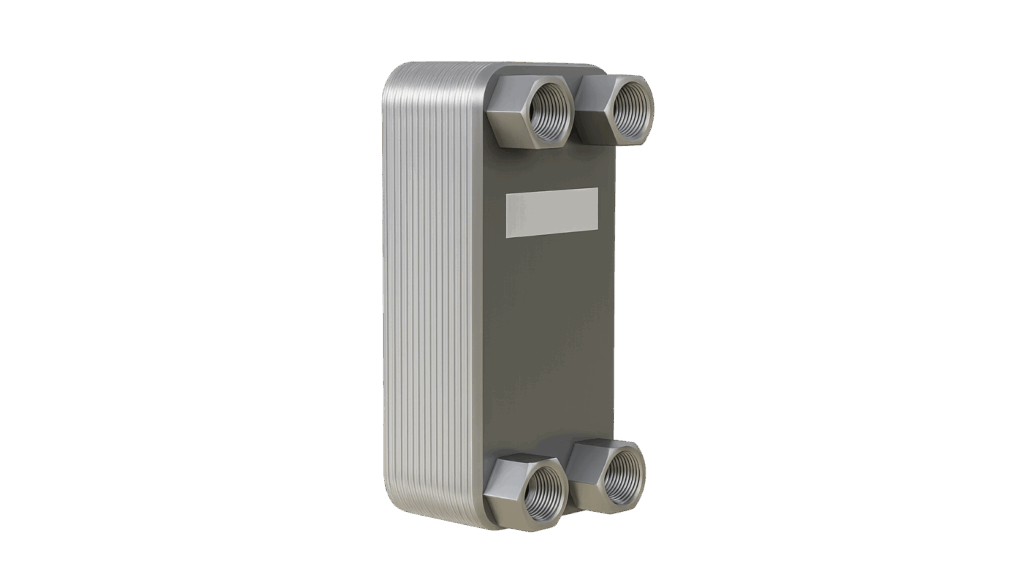

Plate heat exchangers from Stemotech

Compact, powerful and versatile – for precise heat transfer with minimum space requirements.

Stemotech plate heat exchangers combine high thermal efficiency with a compact design. Whether brazed, bolted or welded – we supply the right solution for your medium, your process conditions and your industry. Flexibly configurable, robustly designed and precisely tailored to your requirements.

Key Facts

- Versions: Soldered, screwed or welded

- Materials: Stainless steel (standard), optional titanium or special alloys

- Seals: NBR, EPDM, Viton (for screwed versions)

- Operating pressure: up to 31 bar (soldered), up to 16 bar (screwed), higher pressures on request

- Operating temperature: up to 210 °C (soldered), up to 120 °C (screwed), higher temperatures on request

- Media: Hydraulic oils, water, seawater, natural refrigerants (others on request)

Industries & applications

Heating & building technology (underfloor heating, solar systems, drinking water)

Refrigeration & air conditioning technology (evaporators, condensers, superheaters)

Food technology (milk cooling, pasteurization)

Chemical & process engineering

Mechanical & plant engineering

Marine & offshore applications

Case studies

HVAC systems

Brazed stainless steel plate heat exchangers for compact air conditioning systems

Industrial plants

Welded special solution for high pressure ranges with aggressive refrigerants

Food industry

Screwed version with Viton seals for temperature control with sensitive media

Let's find the best cooling solution for your company together!

Stemotech plate heat exchangers - efficient, flexible and equipped for every application

Plate heat exchangers are among the most efficient solutions when it comes to heat transfer between two media – be it water, oil, coolant or process fluid. Thanks to their compact design, they offer high performance with minimal space requirements and are used in a wide range of industries.

Stemotech offers you a wide range of plate heat exchangers:

-

Soldered models for space-saving installation in heating or cooling systems

-

Bolted versions with high ease of maintenance and expandability

-

Welded versions for extreme operating conditions in the oil, gas or chemical industry

Depending on the application and medium, we use stainless steel, titanium or special alloys. The selection of the appropriate sealing material (NBR, EPDM, Viton) or solder (copper, nickel, stainless steel) guarantees optimum safety and durability – even under demanding conditions.

As an independent supplier, we configure your heat exchanger solution precisely according to technical, economic and spatial requirements. Whether standard or custom-made – at Stemotech you receive tailor-made quality with personal advice and fast implementation.

Stemotech plate heat exchanger – maximum efficiency in minimum space.